Harriet loves to share technology and general things with the world. With a background in computer science, she is always on the lookout for new and innovative ways to improve people's lives. She has also been known to share her opinion on the latest episode of Game of Thrones.

Usually, wood chippers feature two distinct chutes for processing wood. Branches are chopped into chips by the first chute, which is the smaller of the two. The second, bigger funnel is equipped with hammers and blades to convert extra plant debris, such as leaves, into mulch. A user can ascertain the kind and thickness of wood that the chipper can handle based on the design of the wood chipper’s blades. A wood-chipping machine’s capacity to handle a load increases with its size.

Blades can work together or on different shafts. When many blades revolve on separate shafts, the branches of the wood will be swiftly and frequently chopped down as they pass through the blades. Blades with meshing are a little slower. However, because they pull the branches into the blades themselves, they are essentially self-feeding. To learn more about wood chipper blades click here. Intermeshed blades also provide a uniform chip size from the wood chipper.

Essential Parts Of Wood Chipper

Wood chippers are incredible machines that are well-known for their ability to break down large, difficult materials into wood chips or mulch of consistent size. This article will explain the basic elements of wood chipper blades, their production procedures, and the roles they each play in guaranteeing precise and efficient chipping.

Blade Make-Up

One of its most crucial components is the substance that is utilized to create wood chipper blades. Given the amount of strain and wear that the chipping process places on them, these blades need to be extraordinarily tough. Premium steel, such as tool steel or high-carbon steel, is widely utilized to make wood chipper blades. The ideal material must have the proper level of toughness to withstand abrasions and knocks in order to maintain its edge sharp.

Novel and Ingenious

The portion of the blade that actually cuts and chips wood or other materials in a wood chipper is called the cutting edge. To be effective and tidy, cuts need to be sharp and exact. Cutting blades can be found in many different forms and styles, including double-edged, chisel-shaped, and straight blades. The intended usage and kind of material the chipper will handle dictate the design in detail.

Blade Formation

The wood chipper blades’ shape is an important component in the chipping procedure. Certain forms and angles are used in the design of blades in order to maximize cutting motion. The shape of the blades affects the chipper’s efficiency as well as the quality of the chips it makes. Numerous elements, such as the blade’s cutting angle, thickness, and profile, are considered throughout the design and manufacturing process of wood chippers.

Adaptable Style

Many wood chipper blades are made to be reversible, which allows you to flip them to reveal a new cutting edge when the old one gets dull or worn. Chipper operators save time and money by reducing the frequency of blade replacements and prolonging the life of the blades.

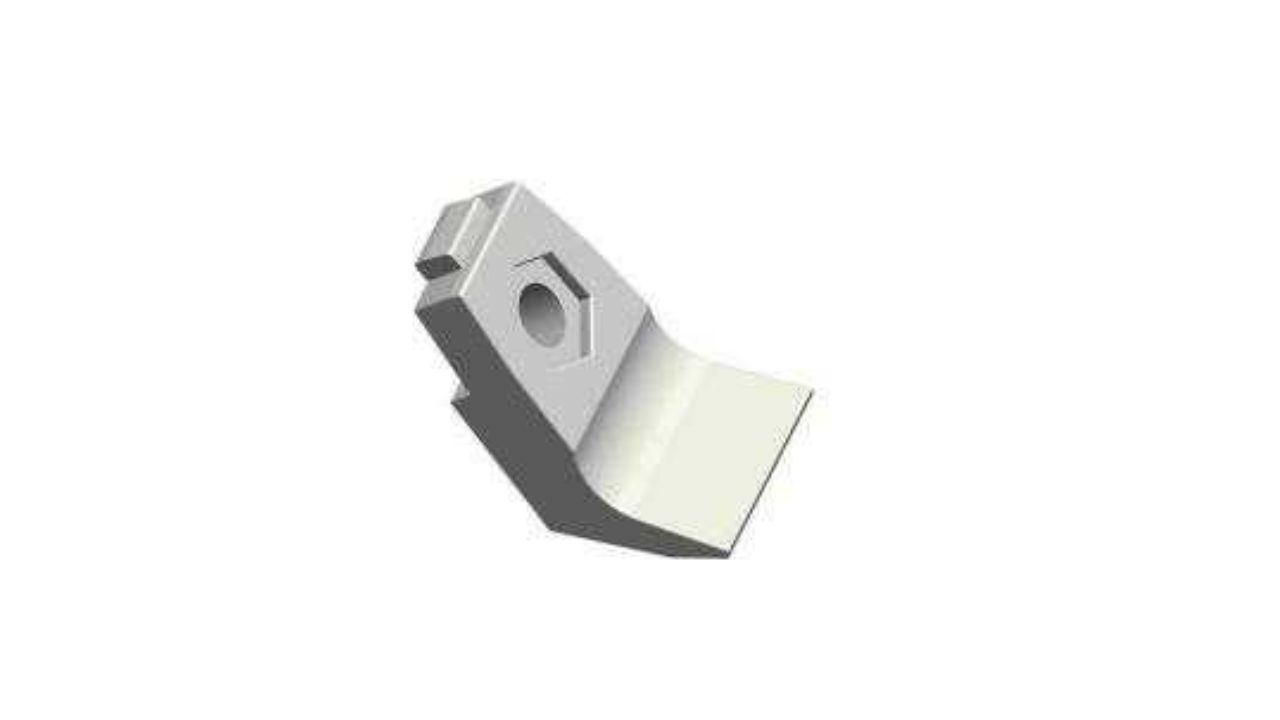

Putting Up Holes

Usually, a revolving drum or disc inside the chipper houses the wood chipper blades. The mounting holes on these blades match the bolts or other fasteners on the drum. For the blades to be firmly fixed and not fall loose while in use, these holes must be drilled precisely. To chip safely and effectively, alignment and fastening must be done correctly.

Reverse Knives

Wood chippers often have counter knives in addition to the main blades. These knives are positioned in opposition to the revolving blades and remain stationary. By causing a shearing action against the revolving blades, they aid in the chipping process. The way the counter knives and chipper blades interact contributes to the consistent and uniform production of wood chips.

Put On Resistance

Wood chipper blades must be strong and resistant to wear since they come into constant contact with abrasive materials. Many blades are subjected to specialist coatings or hardening procedures in order to improve wear resistance. These treatments lengthen the blades’ lifespan and lower the need for replacements.

Conclusion

Wood chippers’ hidden heroes that power their precision and efficiency are their blades. To guarantee that the blades can bear the stress and demands of chipping wood and other materials, numerous crucial components are painstakingly incorporated into their design. These components include the type of blade material, heat treatment, counter knives, reversible design, geometry, mounting holes, and cutting edge.